CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-1

CHAPTER 7

Hazardous and Recycled

Waste

This chapter describes the accumulation, tracking, and transport of hazardous

wastes from generation to ultimate disposal. It includes:

Guidelines for determining if a waste is Resource Conservation and Recovery

Act (RCRA) hazardous

Three categories of hazardous waste generators that are regulated according

to the amount of waste they generate monthly

A summary of the more lenient requirements for hazardous waste that is

recycled (such as used oil and universal waste)

The waste minimization certication requirement

7.1 Regulatory Background

The hazardous waste management program is continuously modied through

new regulations, policies, and congressional mandates. This chapter presents

an overview of some of the most complex regulations developed by the U.S.

Environmental Protection Agency (EPA).

In 1976, Congress passed RCRA because of the national problems with waste

disposal. Several goals of RCRA were to protect human health and the envi-

ronment, reduce waste, conserve energy and natural resources, and reduce

or eliminate the generation of hazardous waste as quickly as possible. To

satisfy the RCRA directive, EPA developed regulations for three categories of

hazardous waste handlers: generators, transporters, and treatment, storage,

disposal and recycle facilities (TSDRFs). This chapter presents an overview of

the regulations applicable to hazardous waste generators in Title 40 of the Code

of Federal Regulations, Parts 261 and 262 (40 CFR 261 and 262). If you manage

a TSDRF, there are additional requirements (for example, daily, weekly and

monthly inspections) that are not outlined in this chapter.

The framework of the hazardous waste regulations was developed for industrial

process waste. These regulations were not intended to regulate contaminated

media and other waste resulting from cleanups. EPA regulations for the man-

agement of contaminated media (soil and groundwater) and other remediation

waste took eect June 1, 1999. Most states have adopted the federal require-

ments for the management of hazardous remediation waste or their own more

stringent programs. Refer to

Chapter 8, Assessment and Cleanup

for more infor-

mation on site assessment and cleanup.

All generators of solid waste,

including fuel facilities, must

determine if any of their waste is

hazardous (40 CFR 262.11).

A solid waste is a hazardous

waste if it exhibits a characteristic

of a hazardous waste or is listed

as a hazardous waste (40 CFR 261

Subparts C and D).

Mixtures of solid and hazardous

wastes can still be hazardous

wastes (40 CFR 261.3(a)(2)(iv)).

Per 40 CFR 262, all large and

small quantity generators must:

– Get an EPA identication (ID)

number.

– Follow accumulation and storage

requirements.

– Meet pretransportation require-

ments of packaging, labeling,

and marking.

– Prepare for accidental releases.

– Use e-Manifest and land disposal

notication forms to track haz-

ardous wastes.

– Keep records and report data.

If you decide to discard or

dispose of your used oil, batteries,

uorescent lamps, or cathode

ray tubes rather than recycle

them, you may have to meet

more stringent hazardous waste

regulations (40 CFR 279.10, 40

CFR 273.1, and 40 CFR 261.4(a)

(22)).

The Law Says

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-2

7.1.1 Hazardous Waste Determination

A hazardous waste is a discarded solid, semisolid, liquid, or contained gas that

can be described as follows:

Because of its quantity, concentration, or its physical, chemical, or infectious

characteristics, it poses a present or potential hazard to human health or the

environment when improperly treated, stored, transported, disposed, or other-

wise managed.

Examples of potentially hazardous wastes that may be generated at DLA Energy

facilities include tank-bottom sludge and wastewaters, unusable waste fuel, waste

solvent, waste paint (non-latex), sandblasting residue, mercury switches, uores-

cent bulbs, aerosol cans, used oil, spill cleanup residues, and expired chemicals.

Waste determination begins at the point the waste is rst generated. In the RCRA

regulatory framework, hazardous waste must rst be identied as solid waste.

The term solid waste refers to any discarded material (in a solid, liquid, semisolid,

or contained gaseous state) that is abandoned, accumulated, recycled, or inher-

ently waste-like (poses a threat to human health and/or the environment) (refer

to 40 CFR 261.2). A discarded material also can be a military munition identied

as a solid waste in 40 CFR 266 Subpart M.

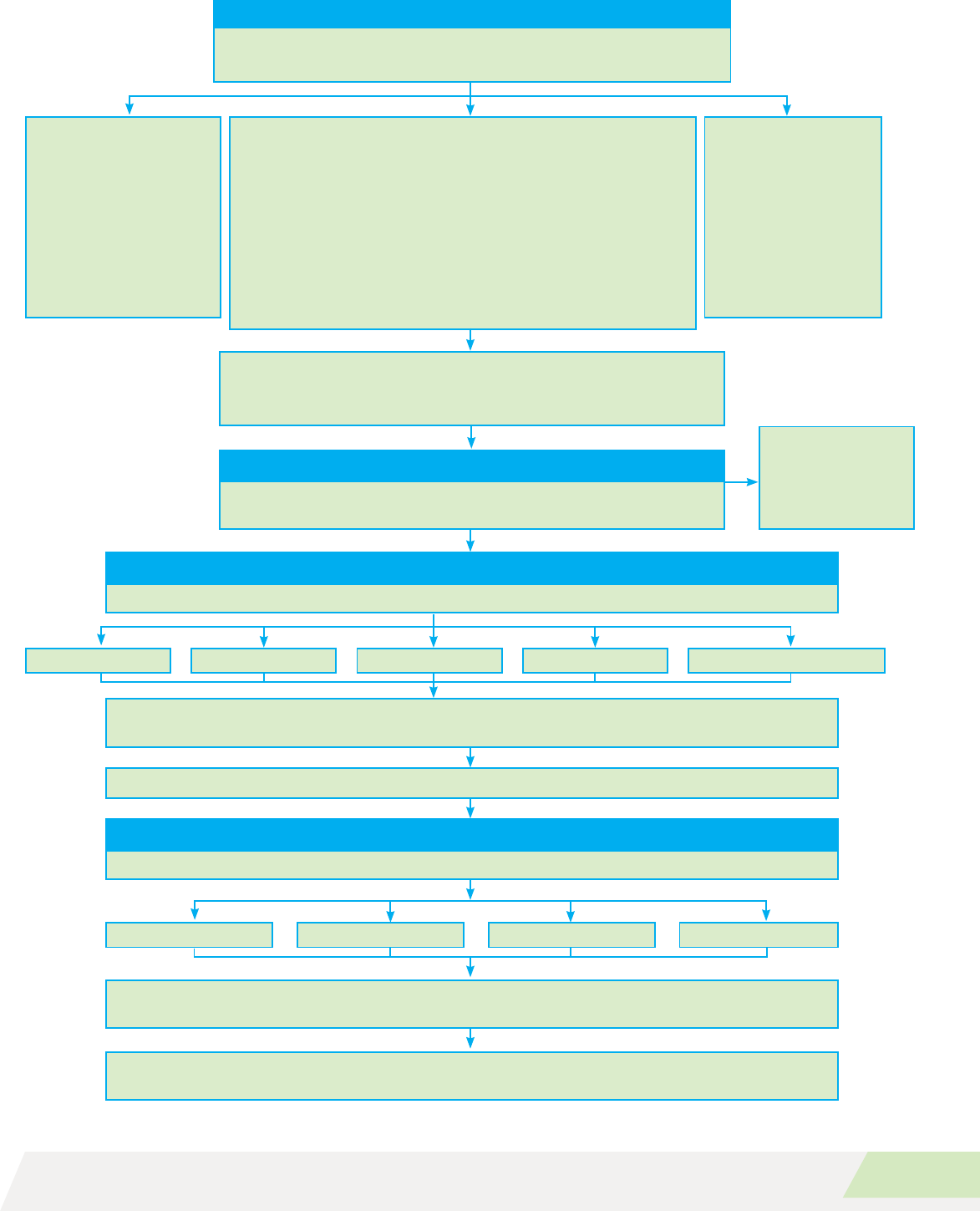

You are responsible for determining if any solid waste generated at your facility is

hazardous by taking the steps listed in Exhibit 7−1.

EXHIBIT 7−1

Steps to Determine if Your Solid Waste is Hazardous

1. Verify if the waste is excluded from regulation under 40 CFR 261.4 and 261

Subpart E. If it is not

excluded, then go to Step 2.

2. Verify if the waste is listed as a hazardous waste in 40 CFR 261 Subpart D.

Continue to step 3.

3. Determine if the waste exhibits any of the characteristics identied in 40

CFR 261 Subpart C by either by:

Sending a sample of the waste to an accredited laboratory for testing according

to specic EPA

methods, or

Using your knowledge of the waste and how it was generated to determine

if it meets the

denition of characteristic hazardous waste.

4. Determine if it is one of the specic hazardous wastes that has been

exempted from regulation under 40 CFR 261.6 (refer to the Recycled

Hazardous Waste section later in this chapter).

For analytical testing services, DLA Energy has access to about 150 U.S. contract

laboratories through the DLA Installation Management for Energy. For more

information, call the Environmental Division at (571) 767−5482 (DSN 427).

EPA assigns four-character alphanumeric waste codes to specic hazardous

waste (for example, D001). All applicable hazardous waste codes must be

identied for each individual waste. The ow charts in Appendix 7−1 will help

you determine whether your waste is hazardous and what regulations apply to

your waste.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-3

7.1.2 Listed Hazardous Waste

EPA lists approximately 500 wastes that it considers hazardous to human health

or the environment. Listed hazardous wastes are those that appear on any

one of the following four lists contained in the RCRA regulations (40 CFR 261.30

through 261.33).

F-listed wastes commonly produced by various industrial processes and gener-

ated from non-specic sources, such as solvents used for cleaning and degreas-

ing (not process-specic).

K-listed wastes generated from industry-specic manufacturing processes (such

as wood preserving and petroleum rening). None of the K-listed wastes are

typically generated at fuel facilities.

P-listed wastes discarded or o-specication commercial chemical products

and resulting residues from containers and spills. This list is applicable to techni-

cally pure

-

grade chemicals once they are discarded, spent, or spilled. Note that if

there is another chemical in addition to the P-listed chemical in the product and

the P-listed chemical is not the sole active ingredient, then any waste product is

NOT a P-listed waste. The P-

listed wastes are called acute hazardous wastes (H)

or (AHW) and are more strictly regulated than other hazardous wastes.

U-listed wastes—also pure−grade discarded or o−specication commercial

chemical products, residues, and spills. The U-listed wastes are identied as toxic

wastes (T).

Any wastes that meet the listing criteria or mixtures of listed waste and other

waste generated at your facility are considered hazardous waste.

7.1.2.1 Hazardous Waste Characteristics

If a solid waste exhibits one or more of four physical or chemical properties

deemed hazardous to human health or the environment by EPA, it is a character-

istic hazardous waste (40 CFR 261.20 through 261.24). The four hazardous waste

characteristics are ignitability, corrosivity, reactivity, and toxicity.

Ignitability

A solid waste is ignitable if it can readily catch re and sustain combustion. A

liquid waste is ignitable if it has a ash point (the temperature at which combus-

tion occurs) of less than 140˚Fahrenheit (˚F). Examples of ignitable wastes include

oil-based paint wastes, non-halogenated degreasers, thinners and solvents

(petroleum distillates), stripping agents, epoxy resins, adhesives, rubber cements

and glues, and some waste inks. An ignitable waste is given the EPA Hazardous

Waste Number D001.

Corrosivity

A waste is corrosive if it is a liquid and dissolves metals and other materials, or

burns the skin or eyes on contact. Liquids with a pH of 2 or less, or 12.5 or more,

are corrosive. Examples of corrosive wastes include alkaline degreasers, corrosive

cleaning solutions, rust removers, waste acids, and bleach compounds (peroxide

and chlorine compounds). A corrosive waste is assigned the EPA Hazardous Waste

Number D002.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-4

Reactivity

A waste is reactive if it is normally unstable and undergoes rapid or violent

chemical reactions, such as catching re, exploding, or giving o fumes when

exposed to water or air. Examples of reactive wastes are bleaches and hypo-

chlorites from water treatment processes, areosol cans with pressure remaining,

lithium batteries, and discarded munitions or explosives. A reactive waste has

the EPA Hazardous Waste Number D003.

Toxicity

A waste exhibits the toxicity characteristic if it has concentrations of heavy metals

or certain organic compounds above specied levels (Appendix 7−2) that may

cause illness or death if inhaled, swallowed, or absorbed through the skin. Long-

term eects of a toxic waste on human health may include cancer, birth defects,

reproductive anomalies, brain and kidney damage, and diseases of the skin,

lungs, and heart. The analytical procedure used to determine if a waste is toxic is

the Toxicity Characteristic Leaching Procedure (TCLP).

Examples of toxic wastes are inks and sludges containing certain heavy metals,

batteries containing lead, certain pesticides, and paint wastes containing heavy

metals, such as chromium or lead. A toxicity characteristic waste has the EPA

Hazardous Waste Number that corresponds to the toxic contaminant causing it to

be hazardous (D004 through D043).

7.1.2.2 Mixtures

Nonhazardous wastes mixed with hazardous wastes become hazardous wastes

(with a few regulatory exceptions). Mixing nonhazardous waste with hazardous

wastes to dilute hazardous waste is not allowed. Mixing these types of wastes

simply creates a larger volume of hazardous waste to manage. Make sure you

separate nonhazardous and hazardous wastes.

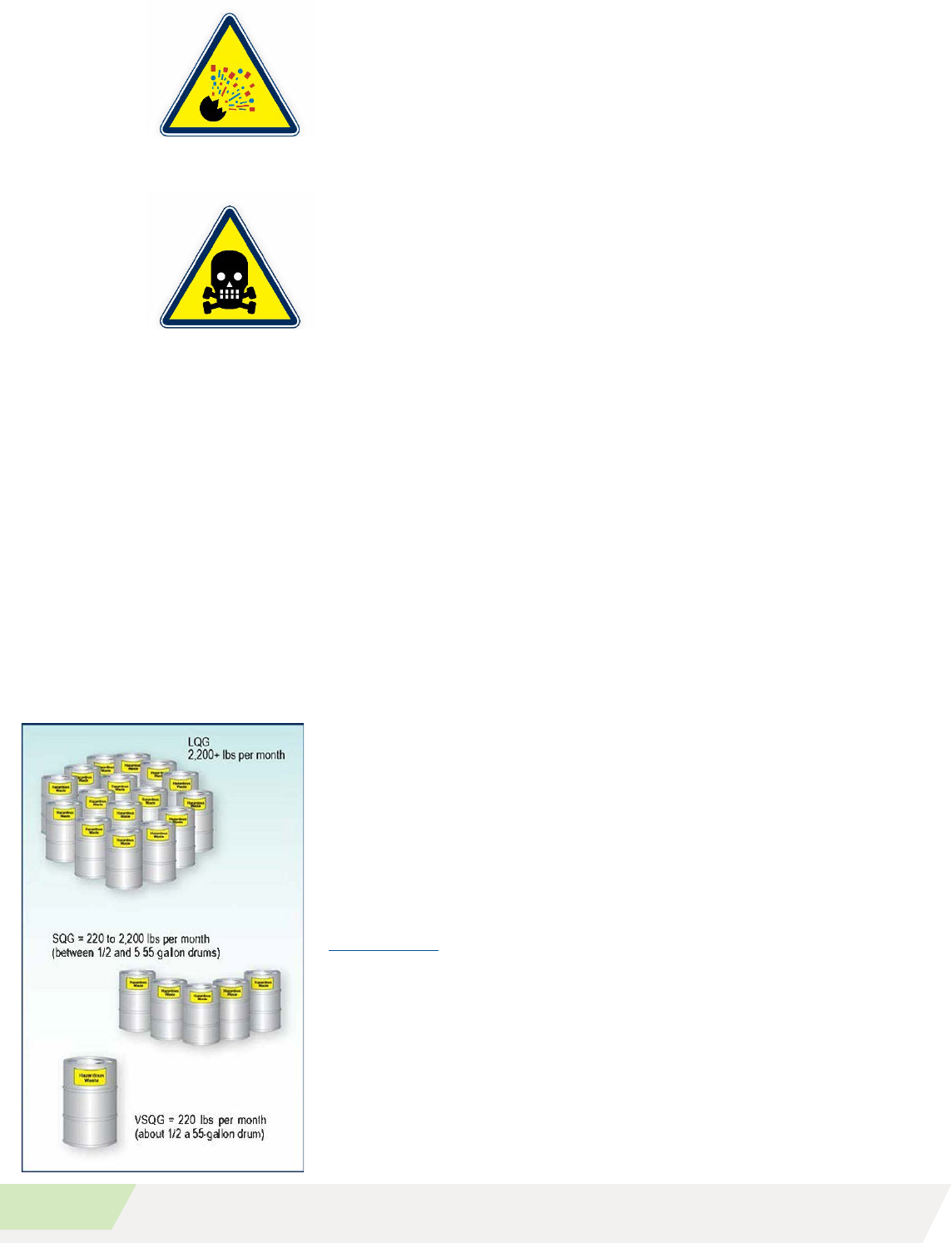

7.1.3 Hazardous Waste Generators

Under RCRA, hazardous waste generators are classied according to how much

hazardous waste they generate in a calendar month. The three categories of

hazardous waste generators are:

Large quantity generators (LQGs)

Small quantity generators (SQGs)

Very small quantity generators (VSQGs)

Appendix 7−3

helps dene your generator category and compares requirements

for the three types of generators.

The following text summarizes generator categories and regulatory requirements

(see 40 CFR 260 and 262 for detail on large and small quantity generators). State

regulations can vary in the denitions and requirements for the three generator

categories. Be sure to check with your state hazardous waste program.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-5

7.1.3.1 Large Quantity Generators

LQGs generate 1,000 kilograms (kg) (about 2,200 pounds [lb] or ve 55-gallon

drums) or more hazardous waste per month, over 1 kg (2.2 lb) of AHW per month,

or over 100 kg of any residue or contaminated soil or debris resulting from an

AHW spill in a month.

7.1.3.2 Small Quantity Generators

SQGs generate over 100 kg (about 220 lb or half of a 55-gallon drum) but under

1,000 kg of hazardous waste per month, and accumulate no more than 6,000 kg

(about twenty-eight 55-gallon drums) at any one time. SQGs also generate no

more than 1 kg of AHW or 100 kg of AHW-contaminated debris per month and

may accumulate no more than 1 kg of AHW or 100 kg of AHW-contaminated

debris at any one time. If the quantity of hazardous waste you produce in a

month exceeds these limits, you become an LQG for that month and must meet

LQG requirements.

7.1.3.3 Very Small Quantity Generators

VSQGs generate no more than 100 kg of hazardous waste, no more than 1 kg of

AHW, and no more than 100 kg of any AHW-contaminated debris in a calendar

month. Special requirements for VSQGs are listed in 40 CFR 262.14. Though

exempt from full regulation, VSQGs must still:

Determine if any wastes generated are hazardous.

Accumulate no more than 1,000 kg of hazardous waste, 1 kg of AHW, or 100

kg of AHW-contaminated debris at any one time.

Treat or dispose of the hazardous waste or AHW in an on-site facility or

ensure delivery to an o-site commercial treatment or disposal facility. These

facilities must be one of the following:

• Permitted or interim status-permitted under RCRA;

• Permitted, licensed, or registered to manage municipal or industrial solid

waste;

• A large quantity generator under the control of the same person as the very

small quantity generator; or

• Recycling facilities.

If you are a VSQG and, at any time, accumulate over 1,000 kg of hazardous waste,

all of the accumulated waste is subject to SQG regulations. If you are a VSQG and

generate over 1 kg of AHW or 100 kg of AHW-contaminated debris in a month (or

accumulate over 1 kg of AHW or 100 kg of AHW-contaminated debris at any one

time), all quantities of the AHW are subject to LQG regulations.

7.1.3.4 Episodic Generation

SQGs and VSQG are allowed to maintain their existing generator category in the

event of planned or unplanned episodic generation (that is, generators do not

have to count hazardous waste managed as part of the episodic event when mak-

ing their monthly generator status determination) [40 CFR 262.13(c )(8)]). However,

notications, specic container marking and labeling, and recordkeeping are

required to use this exception (262 Subpart L – Alternative Standards for Episodic

Generation). In addition, a VSQG would be required to obtain an EPA ID number.

VSQGs do not have to get an EPA

ID number or use a manifest to ship

wastes, but some states (and trans-

porters) may require it.

Did You Know?

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-6

7.1.4 Large and Small Quantity Generator Requirements

For the most part, the regulations that apply to LQGs also apply to SQGs. The only

regulatory relief given to SQGs is that several administrative and training require-

ments are not formally required.

7.1.4.1 EPA ID Number and Generator Status

As an LQG or SQG, you must get an EPA ID number. You cannot treat, store,

dispose of, or turn over for transport any hazardous waste without rst receiving

an EPA ID number. You also cannot deliver your waste to transporters or TSDRFs

that have not received an EPA ID number.

To obtain an EPA ID number, call or write your state hazardous waste agency or

EPA regional oce and ask for a copy of EPA Form 8700−12, Notication of RCRA

Subtitle C Activity Instructions and Form, or check online. Some states use a

dierent form than the EPA form, so contact your state agency rst. Also, you are

required to notify EPA of any changes to the information on the original notica-

tion form, including changes in the facility contact person named, waste codes

identied, and generator status (LQG, SQG, or VSQG).

7.1.4.2 Re-notication EPA ID Number and Generator Status

An LQG must re-notify EPA or authorized state by March 1 of each even-num-

bered year thereafter using EPA Form 8700-12 and may submit this renotication

as part of its Biennial Report required under 262.41.

An SQG must renotify EPA or authorized state starting in 2021 and every four

years thereafter using EPA Form 8700−12. This notication must be submitted by

September 1 of each year in which re-notications are required.

7.1.5 Accumulation of Wastes Without a Permit

Hazardous waste may be accumulated on-site prior to transportation and dispos-

al. However, RCRA regulations limit the period of accumulation.

7.1.5.1 Large Quantity Generators

As an LQG, you may accumulate hazardous waste for up to 90 days if you meet

the following requirements:

Proper storage – Comply with storage standards for containers and tanks,

including air emission standards. Note that the tank design requirements are

detailed and require Professional Engineer (PE) certication (see

Chapter 4,

Aboveground Storage Tanks and Containers

). Mark containers with the words

“Hazardous Waste,” the hazards of the waste, and the date accumulation

began. Conduct and document proper operating, maintenance, and

inspection procedures.

Preparedness and prevention – Operate and maintain your facility to minimize

the possibility of a re, explosion, or spill that could threaten human health

or the environment. The kind of wastes you store will determine the type

of equipment you need, such as communication devices, re control

equipment, and spill control and decontamination equipment.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-7

Maintenance of adequate aisle space – Make sure you have enough room for

unobstructed movement of personnel or emergency equipment. Set up

prior emergency arrangements with the police, re department, emergency

response teams, and local hospitals.

Contingency plan and emergency procedures – Write a contingency plan

describing the actions personnel take in response to emergencies. Have

an Emergency Coordinator on-call at all times to implement the plan.

Refer to Chapter 1, Environmental and Emergency Response Planning.

Personnel training – Train all facility personnel in hazardous waste

management and emergency procedures, equipment, and systems. (Refer to

Chapter 10, Training

).

Closure – When the hazardous waste central accumulation areas are no

longer needed, close them in a manner that minimizes the need for further

maintenance and protects human health by controlling, minimizing,

or eliminating the escape of hazardous constituents to the ground,

surface water, or atmosphere. There are specic closure notications and

performance standards that must be met; see 40 CFR 262.17(a)(8). During

the closure period, all contaminated equipment, structures, and soil must

be properly disposed of or decontaminated. All hazardous waste generated

in the closure process must be handled in accordance with all applicable

requirements. As an LQG, if you store hazardous wastes for more than 90

days, you are considered a storage facility and need a costly and time-

consuming permit. But if your wastes are on-site for more than 90 days

under temporary and uncontrollable circumstances, you can request an

extension of up to 30 days from EPA or your state agency without becoming

a storage facility.

7.1.5.2 Small Quantity Generators

As an SQG, you can accumulate hazardous wastes on-site for up to 180 days

without a permit if you meet all of the following requirements:

Do not accumulate more than 6,000 kg on-site (13,200 lb or about twenty-

eight 55-gallon drums).

Accumulate wastes properly in containers or tanks marked with the words

“Hazardous Waste,” identify the hazards of the waste, and indicate the date

accumulation began.

Meet preparedness and prevention procedures outlined above for an LQG.

Have an Emergency Coordinator on-call at all times to implement the

contingency plan.

Chapter 1, Environmental and Emergency Response

Planning

.

Post basic safety information near the phone where hazardous waste is

stored, including phone numbers and locations of re and spill control

material.

Train employees in waste handling and emergency procedures (Refer to

Chapter 10, Training

).

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-8

Note: If you are an SQG and must transport your waste over 200 miles for o-site

treatment, storage, or disposal, you may accumulate your waste on-site for 270

days or less without a permit if you meet the stated criteria.

As an SQG, if you accumulate hazardous waste for more than 180 or 270 days,

you are considered the operator of a storage facility and need a permit. Under

temporary, uncontrollable circumstances, EPA or your state agency may grant an

extension of up to 30 days beyond the 180- or 270-day period without becoming

a storage facility.

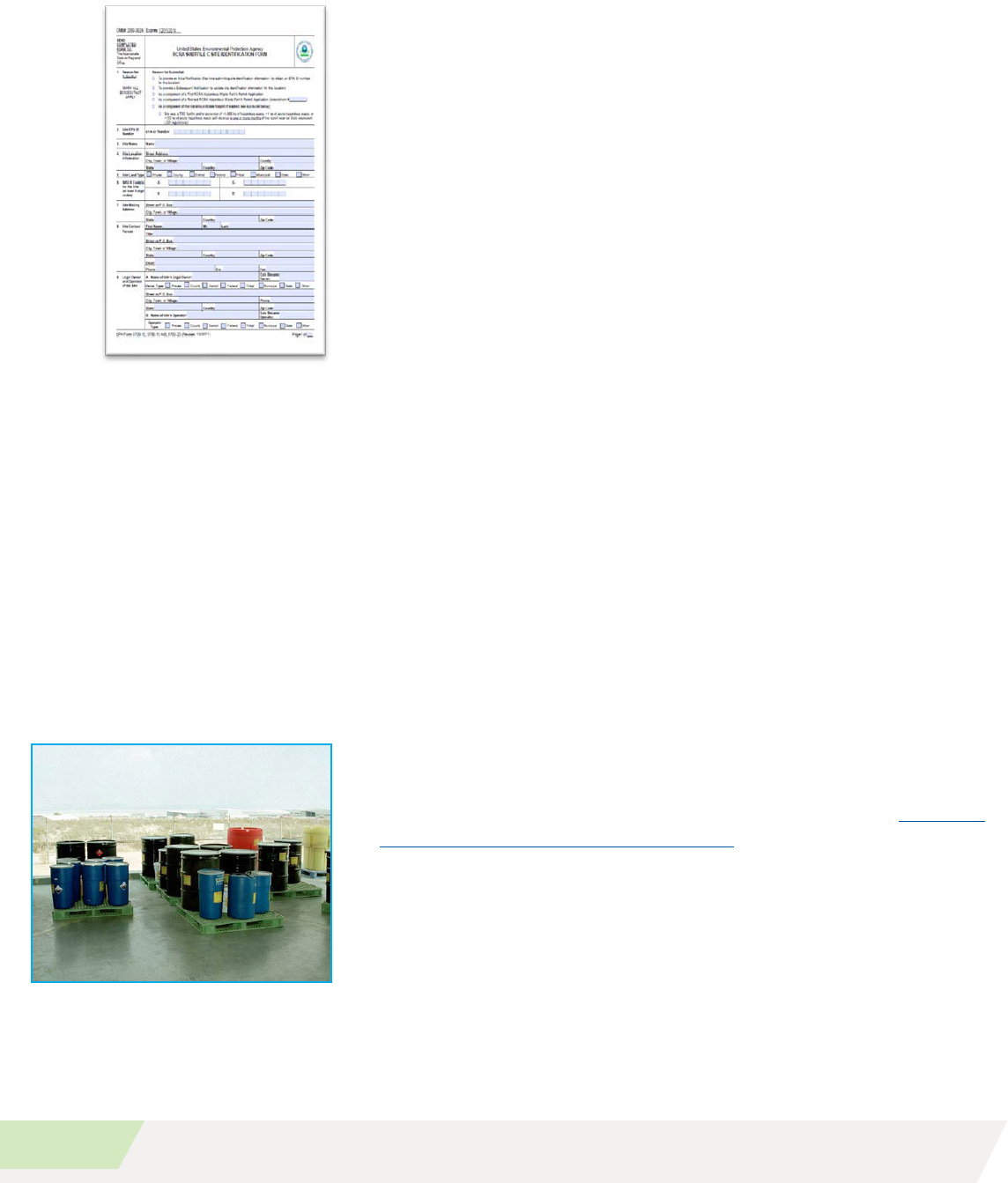

7.1.6 Satellite Accumulation

Federal regulations allow limited quantities of hazardous waste to accumulate at

or near the point of generation (called satellite accumulation areas [SAAs]) for

more than the 90- or 180-day periods specied previously, provided the wastes

are properly managed. At a SAA, generators are allowed to:

Up to 55 gallons of hazardous waste per waste stream (process generating

waste) or 1 quart of AHW at or near the point of generation, as long as the

container is generally visible to the person generating the waste.

Accumulate wastes in containers or drums that are in good condition; are

compatible with the material stored; are kept closed during accumulation

except to add, remove, consolidate waste, or, when venting the container

is necessary, prevent a dangerous situation; and are marked with the

words “Hazardous Waste” and other words that identify the hazard(s) of the

contents.

Once the 55-gallon or 1-quart limit has been reached, immediately mark the

container with the current date and transfer the waste within 3 days to a 90-day

(LQG) or 180

-

day (SQG) central accumulation area or o-site to a TSDRF. The 90- or

180-day accumulation period begins when the satellite accumulation container is

full and dated.

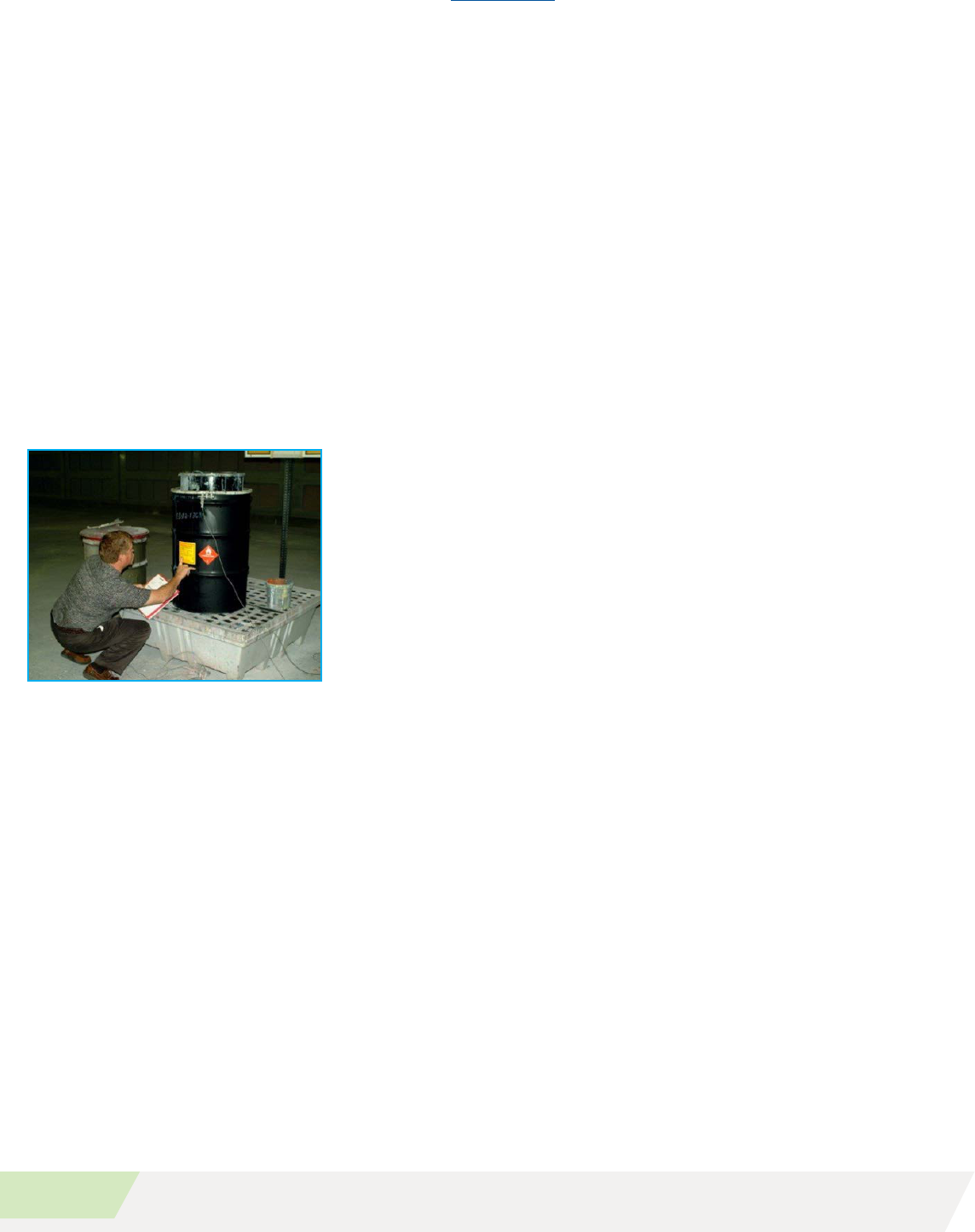

7.1.7 Inspections

LQGs and SQGs are required to inspect, at least weekly, areas in which hazardous

waste is accumulated (central accumulation areas: 90- or 180-day accumulation

areas). Curbs, diking, and concrete surfaces must be checked for signs of crack-

ing or deterioration. Containers must be inspected to ensure that they are not

leaking, that all containers are secured, and that they have lids and bungs tight

and in place. Results of the inspection must be documented, and the inspector is

responsible for making sure problems are corrected immediately. Although not a

federal or state requirement, generators may inspect SAAs on a weekly or month-

ly basis, refer to your site’s hazardous waste management plan.

LQGs and SQGs must inspect emergency systems and equipment near hazardous

waste accumulation areas to ensure proper operations during an accidental spill.

This consists of checking facility communications systems or alarm systems, re

protection equipment, spill control supplies, and decontamination equipment.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-9

7.1.8 Land Disposal Restrictions

Land disposal restriction (LDR) rules, found in 40 CFR 268, restrict the disposal

of hazardous wastes in landlls unless the waste meets certain treatment stan-

dards or a waiver has been obtained. Typically, the TSDRF treats the wastes before

placing them in the landll. If you are an LQG or SQG, you must send an LDR

notication or certication form with the initial shipment of the hazardous waste

to a specic TSDRF. In general, this form identies the proper treatment standard.

Many TSDRFs provide these forms, but it is the generator’s responsibility to make

sure the form is accurate and complete. If the waste, process, or receiving TSDRF

changes, another LDR notication is required.

If you choose to treat your waste on-site (for example, neutralization) to meet the

LDRs before sending the waste for disposal, you will also need to prepare and

comply with a waste analysis plan (40 CFR 268.7(a)(5)). Note that most hazardous

waste treatment requires getting a permit. Check with your state before treating

your waste at your installation. Note that most hazardous waste treatment re-

quires a permit. Check with your state before treating your waste at your facility.

7.1.9 Air Emissions

Air emissions from hazardous waste containers, tanks, equipment leaks, and

process vents are regulated under 40 CFR 265 Subparts AA, BB, and CC (40 CFR

265.1030− 1091). For most DLA Energy facilities, the requirements of 40 CFR

265 Subpart CC, Air Emissions Standards for Tanks, Surface Impoundments, and

Containers, will be most applicable. These Subpart CC regulations apply to haz-

ardous wastes with a volatile organic (VO) concentration of 500 parts per million

by weight (ppmw) at the point of generation. Gasoline and many solvents exceed

this VO threshold. The concentration of the VOs in the waste does not need to be

determined analytically; the facility can assume that the concentration exceeds

the 500 ppmw and implement the requirements.

Hazardous waste containers (such as drums) with a capacity greater than 26

gallons must:

Be a U.S. Department of Transportation (DOT)-approved container

Operate with no detectable organic emissions or be vapor tight

Have covers, lids, and closure devices for each opening that are in place at all

times (except when adding, removing, or consolidating waste)

Open-top containers can be used if they have an organic vapor-suppressing

barrier or foam over the VO material. In addition, containers could be vented to a

control device (such as a combustion unit or are) or in a building with a closed-

vent system to a control device. You must maintain records of the inspections and

the VO concentrations at your facility.

These regulations do not apply to containers used for satellite accumulation or

SQGs of hazardous waste.

There are similar air emissions control requirements for hazardous waste tanks;

see 40 CFR 265.1085 for specic requirements.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-10

7.1.10 Pre-transport Requirements

To ensure safe transportation of hazardous waste, EPA has adopted DOT hazard-

ous materials transportation regulations (see 49 CFR 171−180). The transporter

cannot accept hazardous waste for transport unless the waste has been properly

packaged, labeled, and marked and the transporter’s vehicle has been properly

identied with placards (signs), as noted in the following regulations:

Package all waste as specied in 49 CFR 173, 178, and 179.

Label each container as specied in 49 CFR 172 Subpart E. Generally, the label

is diamond-shaped and shows the hazard class of the waste.

Mark each package of hazardous waste as specied in 49 CFR 172 Subpart D.

As specied in 40 CFR 262.32, mark each container of 119 gallons or less with

the following words and information, according to the requirements of 49 CFR

172.304, either on the package surface or on a label or tag (see Exhibit 7−2).

EXHIBIT 7−2

Hazardous Waste Marking Requirements

HAZARDOUS WASTE —Federal Law Prohibits Improper Disposal. If found, contact

the

nearest police or public safety authority or the U.S. Environmental Protection Agency

.

Generator’s Name and Address

Generator’s EPA Identication Number

Manifest Tracking Number

EPA Hazardous Waste Codes ___________________________________________

Mark the transport vehicle with, or oer the initial transporter, the

appropriate placards as specied in 49 CFR 172 Subpart F. The design of these

placards is usually similar to the package labels.

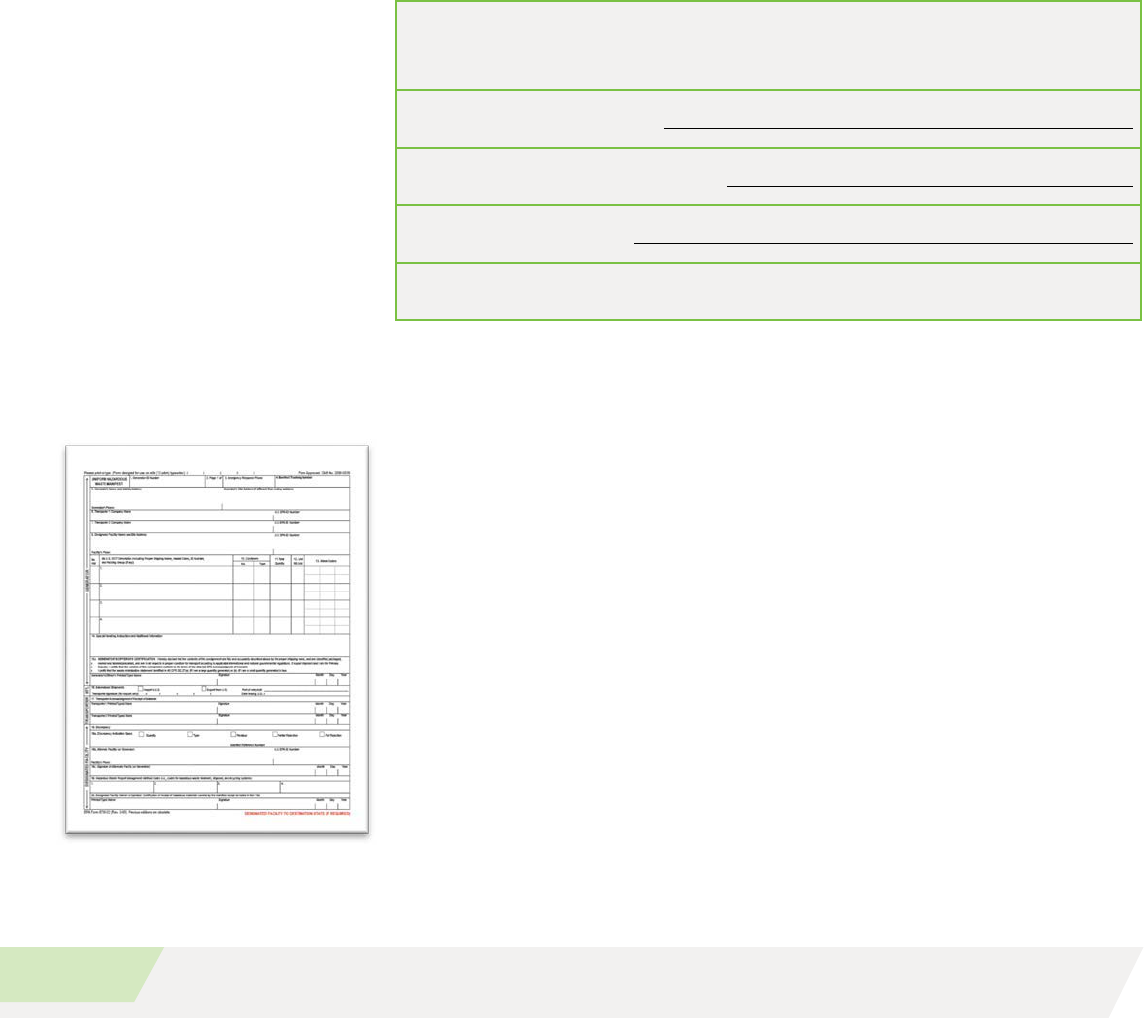

7.1.11 Hazardous Waste Electronic Manifest (e-Manifest)

The hazardous waste electronic manifest (e-Manifest) is a national system for

tracking hazardous waste shipments electronically. Users of the e-Manifest will

need an EPA ID number and must register with e-Manifest.

The e-Manifest system allows for three types of hazardous waste manifest cre-

ation options:

Paper (generator, transporter, and receiving facility all sign on paper)

Hybrid (starts as paper manifest signed by the generator and then is signed

electronically by the transporter and receiving facility)

Electronic (created in e-Manifest and electronically signed by all entities listed

on the manifest)

The e-Manifest contains the following:

Name, address, and EPA ID number of your facility and the TSDRF receiving

the waste

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-11

Name and EPA ID number of the transporter(s)

Types, quantities, and packaging of waste being transported

Emergency contact information and procedures

If you are an LQG, you must certify on each manifest that your facility has a

hazardous waste minimization program in place and that you have selected the

most practical method of treatment, storage, or disposal to minimize the threat

to human health and the environment. If you are an SQG, you must certify that

you have made a good faith eort to minimize hazardous waste generation and

to select the best waste management method available.

To track the waste, the e-Manifest must be electronically signed each time the

waste is transferred (from your facility to a transporter, from transporter to

transporter, and from transporter to the designated facility). Your facility, each

transporter, and the designated facility should each keep a copy of the manifest

(some states also require a copy to be mailed to them). After the waste has

reached the designated facility, the owner or operator of that facility must send

an electronic copy to EPA. Generators are required to track their shipments in the

e-Manifest database to ensure their waste was received at the destination facility

in a timely fashion.

Note that in 2012, EPA issued a nal rule that modies the polychlorinated

biphenyl (PCB) management rules so that the inclusion of PCBs, which are not

considered RCRA hazardous wastes, on the waste manifest is consistent with

RCRA regulations.

7.1.12 Recordkeeping and Reporting

The three main recordkeeping and reporting requirements include:

Biennial reporting (sometimes annual or quarterly)

Manifest exception reporting

Records retention (inspections, reports, manifests, waste analyses, and land

disposal notices and certications)

7.1.12.1 Biennial Report

If you are an LQG that ships any hazardous waste o-site to a TSDRF, you must

submit a biennial report (every 2 years) to your state agency by March 1 of each

even

-

numbered year. The report covers your activities for the previous year and

includes the following:

EPA ID number, name, address, and other general and waste information for

your facility

Calendar year covered by the report

Each TSDRF to which waste was shipped during the year and each transporter

used

Description and volume of each hazardous waste shipped o-site

All hazardous waste received from a VSQG

Eorts to reduce the volume and toxicity of the waste generated, including a

comparison of the reductions against the previous years’ waste generated

On October 5, 2012, the Hazardous

Waste Electronic Manifest Estab-

lishment Act was signed into law,

paving the way for a nal electronic

manifest (e−Manifest) rule. The act

authorizes EPA to 1) develop an

electronic hazardous waste mani-

fest system and 2) impose user fees.

EPA required the use of the e-Mani-

fest on June 30, 2018.

Did You Know?

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-12

Note that some states require annual or even quarterly generator hazardous

waste reports.

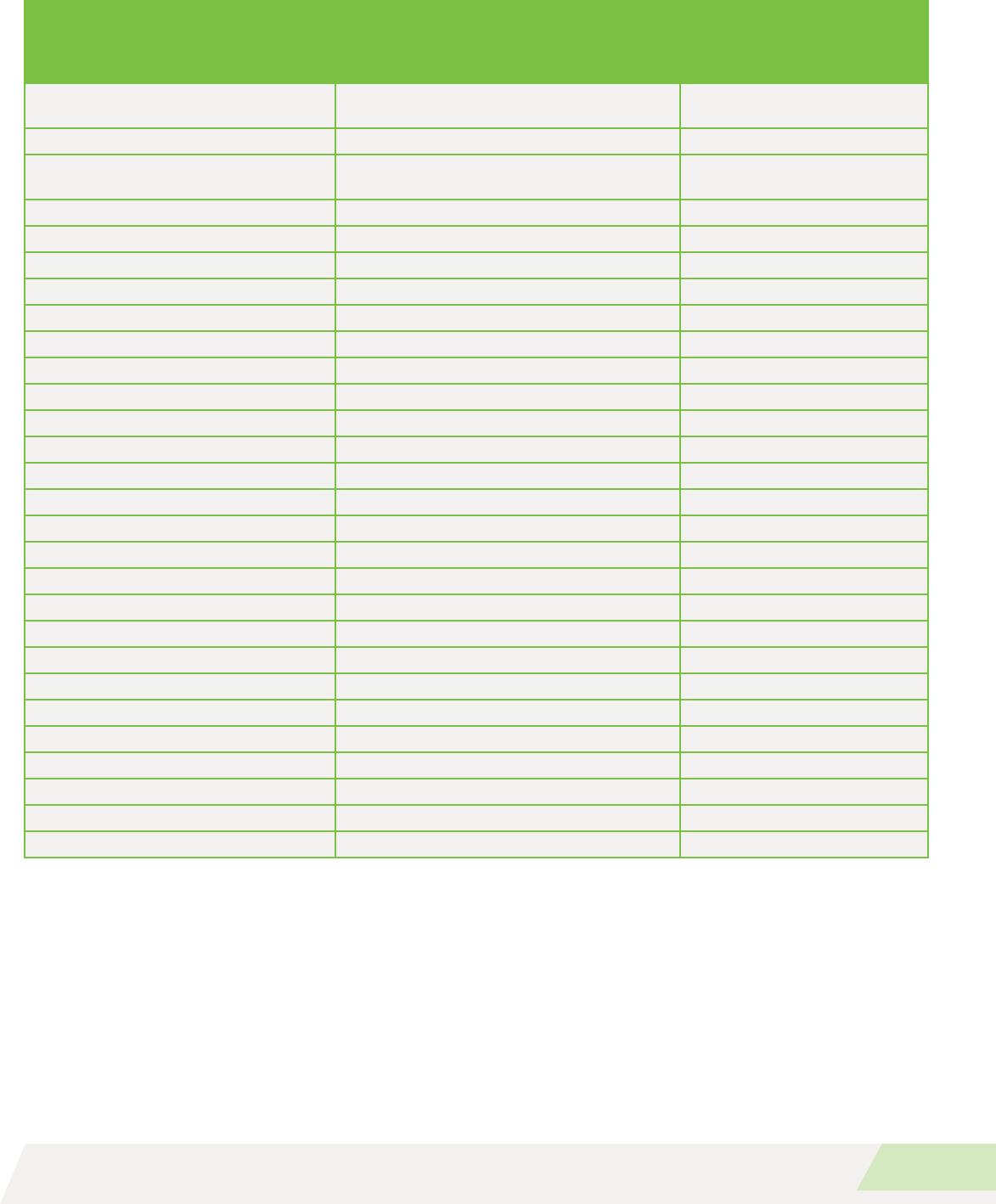

Appendix 7-4

shows the state-specic hazardous waste reporting

requirements.

7.1.12.2 Manifest Exception Report

If you are an LQG and you do not nd a copy of the signed manifest from the

designated TSDRF in the e-Manifest database within 35 days of the date the

waste was accepted by the initial transporter, try to determine the status of the

hazardous waste shipment. If the signed manifest is not in the e-Manifest system

within 45 days of the date the waste was accepted by the initial transporter, you

must submit an exception report to your state agency. Include a copy of the

manifest and a letter explaining what you have done after 35 days to locate the

hazardous waste.

If you are an SQG and you do not nd a copy of the signed manifest from the

designated TSDRF in the e-Manifest database within 60 days of the date the

waste was accepted by the initial transporter, send a copy of the manifest and a

statement that conrmation of delivery was not received to your state agency.

7.1.12.3 Schedule for Keeping Records

Keep a copy of each biennial report (or in some states, the annual or quarterly

report) and exception report for at least 3 years from the due date of the report.

Keep records of any notices, certications, waste analyses data, and other haz-

ardous waste determination documentation for at least 3 years from the date

that the waste was last sent to an on-site or o-site TSDRF. Also, keep a copy of all

manifests until you receive a signed copy from the designated facility via e-Man-

ifest. The manifest from the designated facility must then be kept for at least 3

years from the date the waste was accepted by the initial transporter.

7.2 Recycled Hazardous Waste

The objectives of RCRA are “to promote the protection of health and the environ-

ment and to conserve valuable material and energy resources.” With these goals

in mind, EPA took several steps to encourage hazardous waste minimization and

to promote the reuse and reclamation of useful materials in a manner that is safe

and protective of human health and the environment. One step was to require

hazardous waste LQGs and TSDRFs to certify that they have a waste minimization

program in place that reduces the quantity and toxicity of hazardous waste

generated to the extent economically practicable.

Secondly, EPA wanted to provide incentives to reduce the amount of hazardous

waste needing disposal by encouraging recycling of certain hazardous waste in

a protective manner. Over the years, EPA published special management regu-

lations for select hazardous waste that are recycled. A material is recycled if it is

used, reused, or reclaimed. The process of recycling is still regulated by EPA to

protect against “sham” recycling operations. The recycling regulations in 40 CFR

261 are too complicated and too numerous to summarize in the guide, but a few

examples are noted below.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-13

This section summarizes the less stringent regulations for recycled:

Hazardous Secondary Materials (40 CFR 260.43, 261.2 and 261.4)

Spent Lead Acid Batteries (40 CFR 266.80)

Universal Waste (40 CFR 273) (lead acid batteries also can be managed under

these rules)

Cathode Ray Tubes (40 CFR 261.39 and 261.40)

Used Oil (40 CFR 279)

Solvent-contaminated Wipes (40 CFR 260.10, 261.4(a)(26) and 261.4(b)(18))

Vendors who recycle waste must be certied by the state and should provide a

copy of the certication to the generator prior to sending waste to that vendor.

If these waste materials are not recycled, and they would otherwise meet

the denition of hazardous waste, they are subject to full hazardous waste

regulations.

7.2.1 Recycling Hazardous Secondary Materials

In 2008, EPA modied the denition of solid waste to encourage recycling of

certain secondary materials (for example, spent material, by-product, or sludge)

that would otherwise be hazardous waste if not being recycled. Generators have

to demonstrate that the recycling is legitimate by documenting that it produces

a valuable intermediate or nal product or ingredient and that it is recovered or

regenerated in the recycling process. Secondary materials can be legitimately

reclaimed on-site, recycled o-site by the same company, or recycled o-site

under a tolling agreement or contract between companies.

There are notication requirements and recordkeeping requirements that have

to be complied with if the exemption is being used. It is important that, if this

exemption is being used, compliance with the speculative accumulation storage

limits is not exceeded (that is, you are not just accumulating the material because

you don’t want to dispose of it). Not all states have adopted this exemption;

therefore, be sure to check your state regulations.

7.2.2 Spent Lead Acid Batteries

Lead acid batteries are usually collected and sent for recycling under the exemp-

tion found in 40 CFR 266.80. While being collected, lead acid batteries should be

kept o the oor and should be protected from weather so that you don’t have a

spill of battery acid.

If you collect your lead acid batteries and the battery vendor picks them up for

recycling or you transport the battery to the vendor for recycling, you need to

make sure the batteries are managed properly and sent to a facility that can treat

the batteries to meet the LDR standards.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-14

7.2.3 Universal Waste

Certain commonly generated hazardous wastes are classied as universal waste

when recycled and can be managed under the more lenient universal waste

regulations (40 CFR 273). Universal wastes consist of:

Recalled and unused pesticides

Hazardous waste batteries (such as nickel-cadmium, alkaline, silver-oxide,

lithium, and nickel-metal hydroxide. Lead-acid batteries can also be recycled

under the universal waste rules)

Mercury-containing equipment (such as thermostats, barometers,

manometers, temperature and pressure gauges, and mercury switches)

Lamps (such as uorescent, neon, mercury vapor, high pressure sodium, high

intensity discharge, and metal halide)

Under these regulations, you must label, date, and store the universal wastes so

that they will not break or release material to the environment. Universal wastes

can be stored on-site for 1 year. Small quantity handlers can store no more

than 11,000 pounds (lb) (5,000 kg) of universal wastes; large quantity handlers

can store over 11,000 lb. Both small and large quantity handlers must record

the dates that the universal wastes are placed in storage and the dates that they

are transported o-site, along with a record of the o-site shipment. Generators

who store universal waste must notify their states of this activity using EPA

Form 8700−12.

7.2.4 Cathode Ray Tubes

Cathode ray tubes (CRTs) are vacuum tubes made primarily of glass. They are

part of the video display components of older model televisions and computer

monitors. EPA has determined that lead (along with mercury, cadmium, and arse-

nic) has been used in the manufacture of these CRTs. The lead in color monitors

has been shown to be at concentrations to make the CRTs hazardous waste. The

EPA established a conditional exclusion from the hazardous waste management

regulations for CRTs destined for reuse and recycling. Used or unused CRTs des-

tined for disposal would continue to be solid wastes, and likely hazardous wastes.

If they are hazardous waste, then LDRs for this waste would also be applicable.

Used CRTs from any source sent somewhere else for use “as is” or after minor

repairs, such as rewiring or replacing defective parts, are considered products

“in use” and are not wastes. However, to avoid sham recycling, used intact CRTs

stored for more than 1 year are regulated as hazardous waste.

Many CRTs that cannot be reused are sent for recycling, which consists of disas-

sembling them to recover valuable materials from the CRT, such as lead or glass.

Used, broken CRTs are not regulated as hazardous waste as long as they are:

Destined for recycling or undergoing glass processing

In containers clearly labeled regarding contents

Safely transported in containers designed to minimize releases

Stored in a building or container designed to minimize releases

Stored on-site less than 1 year before recycling them

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-15

Processed glass from used CRTs is also excluded from the denition of solid waste

if it is sent to a glass manufacturer for recycling or to a lead smelter, provided

the glass is stored at your facility for less than 1 year and it has not been placed

outdoors on the ground.

If your facility is classied as a VSQG, the requirements for CRTs do not apply to you.

Check your state regulations to see if they have adopted this rule or have dier-

ent requirements.

7.2.5 Used Oil

Used oil includes oils rened from crude and synthetic oil. It covers lubricating oils,

engine oils, transmission and hydraulic uids, gear oils, water-soluble cutting oil

(known as oil coolants), and electrical oils. In 1992, because of improper disposal of

used oil on the ground, in water, or into sewers, EPA established used oil manage-

ment standards in 40 CFR 279 to encourage recycling of used oil. These regulations

establish specic storage, tracking, and handling requirements for used oil that is

recycled in any manner. Burning as a fuel (for example, in cement kilns and indus-

trial boilers) and re-rening are the two major methods for recycling.

Other examples of used oil managed under the management standards include:

Mixtures of used oil with fuels or other fuel products. However, if the used oil

is mixed on-site with diesel fuel for use in your own vehicles, it is not subject

to used oil regulations once it is mixed

Used oil produced on vessels during normal operations once it is transported

ashore. If you accept used oil from a vessel, you are a co-generator of the

used oil, and both you and the vessel’s owner or operator are responsible for

properly managing the waste

Materials containing or otherwise contaminated with used oil that are

burned for energy recovery

Wastewater that contains de minimis quantities (for example, from small leaks,

spills, or drippings) of used oil are exempt from these standards.

Used oil destined for recycling is regulated under 40 CFR 279, regardless if it is

a characteristic hazardous waste. Some oil may exceed hazardous waste toxicity

characteristic limits because they contain additives that are hazardous constit-

uents or metals, such as arsenic, barium, chromium, zinc, and lead. You will be

required to manage your used oil as a hazardous waste if:

It exhibits a hazardous waste characteristic and is destined for disposal

(instead of recycling).

It is intentionally mixed with hazardous waste (for example, mixed with

solvents).

It contains more than 1,000 part per million (ppm) total halogens (for

example, chlorinated compounds). At that concentration, it is presumed

to be hazardous waste by EPA. Generators may rebut this presumption by

demonstrating that the used oil does not contain hazardous waste (waste

codes F001 or F002) or only contains small quantities of the halogenated

hazardous constituents in 40 CRF 261 Appendix VIII.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-16

7.2.5.1 Used Oil Storage

In addition to the requirements outlined below, used oil generators must com-

ply with all applicable Spill Prevention, Control, and Countermeasure (SPCC)

requirements (40 CFR 112), as well as underground storage tank (UST) standards

(40 CFR 280) for used oil that is stored in underground tanks. Refer to

Chapter

3, Underground Storage Tanks

and

Chapter 4, Aboveground Storage Tanks and

Containers

for more information.

Proper storage – Store used oil in tanks or containers that are in good

condition and marked with the words “Used Oil.” Other materials should not

be mixed with used oil.

Spill response – Stop, contain, and clean up any release of used oil not subject

to the UST release response requirements. Repair or replace any leaking used

oil storage containers or tanks before returning them to service.

Secondary containment – Make sure used oil containers have secondary

containment, such as a dike or curb, to hold 10% of the contents of all the

containers or 100% of the contents of the largest container, whichever is

greater. If stored outside, the containment must have added capacity for

rainfall (for example, 24-hour, 25-year storm).

7.2.5.2 Transportation Requirements

You may not deliver your used oil to transporters who have not obtained an

EPA ID number. You may transport your own used oil without an EPA ID number

provided the following requirements are met:

Transport the used oil in a company-owned or employee-owned vehicle.

Transport no more than 55 gallons of used oil at any one time.

Deliver the used oil to a used oil collection center that is registered, licensed,

permitted, or recognized by a state or local government to manage used oil.

You may transport, without an EPA ID number, used oil generated at your facility

to an aggregation point that you own or operate provided you transport it in a

company-owned or employee-owned vehicle and you transport no more than 55

gallons at any time.

7.2.5.3 Disposal of Non-recyclable Used Oil

Used oils that cannot be recycled must be properly disposed of. Used oil may not

be used as a dust suppressant. Hazardous used oils must be managed in accor-

dance with the hazardous waste management requirements. Non-hazardous

used oils that cannot be recycled must be disposed of at an appropriate solid

waste disposal facility. In some states, non-hazardous used oil is banned from

being disposed of as a solid waste in municipal landlls.

Materials contaminated with used oil (such as rags, wipes, and absorbent ma-

terials) are to be managed under the used oil standards if they are still dripping

with oil. If the material no longer contains free-owing used oil, you need to

determine if it is a hazardous waste. Test the material, or use your knowledge of

the material and type of oil, to determine whether it exhibits a hazardous waste

characteristic (primarily, the toxicity characteristic for metals or benzene). If it

is deemed hazardous, it must be handled as a hazardous waste. If the rags or

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-17

materials are not hazardous, they may be sent to a municipal landll depending

on your state requirements.

7.2.5.4 Used Oil Filters

EPA prefers that used oil lters be recycled once they are properly drained. Many

used oil lters are excluded from the hazardous waste regulations if they are

hot-drained, which means they are drained near engine operating temperatures

or above 60˚F. Filters can be hot-drained using one of the following methods:

Gravity draining – Puncture the lter’s anti-drain valve or dome end and allow

to drain.

Crushing – Squeeze out the used oil and compact the remaining lter

material.

Disassembly – Separate the lter into its dierent parts (metal canisters,

rubber gaskets, and paper lter).

Other equivalent methods – Such as using air pressure to force the oil out of

the lter.

Filters should be stored in covered, rainproof containers. Drained, used oil lters

can usually be recycled in several ways. For instance, the entire lter can be

burned for fuel or the dierent components can be recycled separately. Some

steel mills and scrap metal recyclers may also accept the lters as feedstock.

Terne-plated oil lters are included within EPA’s hazardous waste regulations and

can be recycled. Terne is an alloy of tin and lead. The lead in the terne plating

makes the lter a characteristic hazardous waste.

7.2.6 Solvent-contaminated Wipes

Rags, shop towels, absorbent pads, swabs, and other materials contaminated

with certain hazardous waste solvents (for example, F-listed solvents or wipes

exhibiting the ignitability characteristic) used as wipes are conditionally excluded

from the hazardous waste regulations provided you clean or launder them or

dispose of them properly.

To be excluded as hazardous waste, wipes must be:

Managed in non-leaking, closed containers labeled “Excluded Solvent-

Contaminated Wipes.”

Sent for cleaning or disposal within 180 days from the date of initial

accumulation in the container, and the wipes or container cannot contain

free liquids when being sent for cleaning or disposal.

Sent for reuse to a laundry or dry cleaner that is regulated by the Clean Water

Act (CWA) if they have wastewater discharges.

Sent for disposal to a permitted municipal waste landll or a combustion

facility regulated by the Clean Air Act (CAA).

Free liquids may be removed from the wipes by any number of methods, such

as screen-bottom containers, mechanical wringing, centrifuging, or vacuum

extraction.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-18

A test method called the Paint Filter Liquids Test (EPA Method 9095B) may be

used to determine if solvent-contaminated wipes contain no free liquids. Free

liquids removed from the wipes or the container holding the wipes must be

properly managed as hazardous waste or recycled, as applicable.

The following documentation is required to be maintained at your facility for 3

years from each shipment:

Name and address of the laundry, dry cleaner, landll, or combustion facility

Evidence that the 180-day accumulation time limit is being met (log sheets,

regularly scheduled pickup arrangements, initial accumulation dates on

container labels,

Description of the process used to meet the “no free liquids” condition

Wipes that contained listed hazardous waste other than solvents, or exhibit a

hazardous waste characteristic of reactivity, corrosivity, or toxicity due to contam-

inants other than solvents, are not eligible for the exclusion. In addition, wipes

sent for o-site disposal that contain trichloroethylene are not exempt and are

considered hazardous waste.

Note that exclusions and exemptions from the hazardous waste regulations may

not be available in all states. State hazardous waste programs may be stricter

than the federal rules. Always check your state rules to see if they adopted this or

any other exemption.

7.3 Hazardous Waste Minimization

By signing a hazardous waste manifest and submitting the annual, biennial,

or quarterly report, the generator certies that there is a waste minimization

program in place. EPA issued guidance in 1993 describing the elements of a

hazardous waste minimization program. This consists of:

Preparing a written waste minimization policy and plan

Establishing explicit and achievable goals and tracking system

Training and recognizing employees

Exchanging technical information, ideas, and strategies

Allocating the cost of waste management to the activity that generated the

waste

Be sure to check with your state hazardous waste program to see if they have

additional waste minimization requirements.

Promoting reuse, recycling, and reclamation of hazardous waste, if properly con-

ducted, can avoid environmental hazards, protect scarce natural resources, and

reduce the nation’s reliance on raw materials. The following pollution prevention

(P2) or waste minimization options must be considered in your hazardous waste

minimization program:

Recycling

Material substitution

Engineering controls

Best management practices (BMPs)

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-19

7.3.1 Recycling

Recycle unusable fuel, used oil, sludges, and other materials if possible. Specic

suggestions include:

Re-rene unusable fuel and oil to virgin specication so it can be reused as

motor oil and fuel. You may want to re-rene at an o-site recycling program

through a broker or directly with a re-rening facility.

Drain used oil lters and recycle in several ways: the entire lter can be

burned; scrap metal recyclers may accept lters as feedstock, etc.

Return bulk petroleum, oil, and lubricants (POL) facility lters to the

manufacturer to be recycled. Check with your state regulations to make sure

this is not considered treatment, and coordinate any such eorts with the

lter manufacturer.

Burn used fuel, that is not up to specication for use in aircraft or

automobiles, in generators or industrial heaters rather than disposing of it as

a waste. Generators and heaters can typically burn many types of fuel (such

as diesel, JP−8, or JP−4).

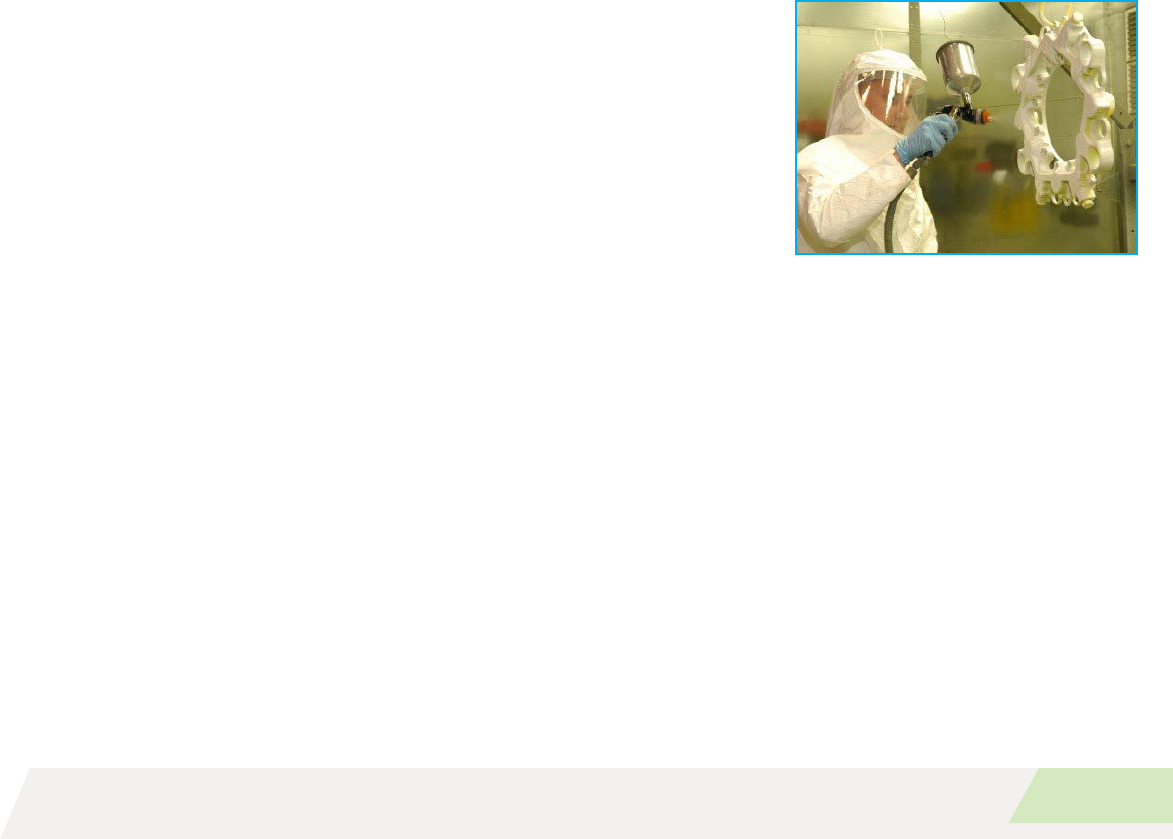

7.3.2 Material Substitution

To reduce the amount of hazardous waste to be disposed, substitute appropriate

materials for sandblast residue, absorbent material, and parts-cleaning solvents.

Sandblast residue − Use latex paints to replace oil-based paints. This reduces

the amount of hazardous sandblast residue because, unlike oil-based paints,

most latex paint waste can be disposed of as non-hazardous waste.

Absorbent material − Use large rolls of absorbent pads. Tear o only the

amount needed and use the pads until they no longer absorb the spilled

material. Because they absorb more and weigh less than other absorbents,

such as vermiculite, pads are cheaper to ship o-site after use.

Parts-cleaning solvents − Use environmentally friendly parts-cleaning

solvents and recycle parts-cleaning solvents when possible.

7.3.3

Engineering Controls

Use engineering controls, such as downstream blending of fuel system icing

inhibitor (FSII), self-supporting geodesic domes on tanks, and improved oat-

ing-roof seals to reduce or eliminate FSII in tank-bottom wastewater.

7.3.4 Best Management Practices

Use BMPs to reduce the amount of hazardous waste you generate:

Good housekeeping − Maintain a clean and orderly work environment

to reduce the possibility of accidental spills caused by mishandling of

equipment and materials.

Visual inspection − Perform routine visual inspections of the facility to uncover

conditions that could cause discharge of hazardous waste. Look for signs of

leaks, corrosion, or other deterioration of all containers that store hazardous

waste.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-20

Employee training − Provide training in hazardous waste management, waste

minimization, and P2 to personnel who handle, or are routinely exposed to,

hazardous waste. (Refer to

Chapter 10, Training

).

Storage container handling − Always handle, open, and store a container with

POL or hazardous waste so the container cannot leak or break.

Waste handling precautions include the following:

Check for the maximum allowable storage temperatures for wastes on Safety

Data Sheets (SDSs) or waste prole data.

Use extreme caution when operating forklifts or other heavy equipment

around waste accumulation and storage points.

7.4 State Requirements

Most state agencies (with the exception of Iowa and Alaska) have received

authorization from EPA to administer hazardous waste programs. Some states

have adopted the federal program outright while others have developed their

own programs that are more stringent or broader in scope than the federal

requirements. It is critical for you to check your state hazardous waste regulations

because of the regulatory variability. Refer to

Appendix E

for a list of state agency

contacts. Below are some examples where states have stricter and diering

requirements than EPA.

7.4.1 Waste Identication

Some state agencies may identify certain waste types as hazardous, special

waste, or industrial waste that would not necessarily be identied and

regulated as such under the federal program. In California, wastes that kill

sh, PCB wastes, oily wastes, and friable asbestos are hazardous waste.

California, Texas, and Washington have a denition for solid corrosive

hazardous waste. Washington regulates persistent hazardous waste

(halogenated compounds and polycyclic aromatic hydrocarbons [PAHs]).

Some other states that regulate additional wastes include Colorado, Illinois,

Indiana, Maine, Maryland, Michigan, Missouri, New Hampshire, Oregon,

Rhode Island, South Carolina, Utah, and Vermont. Always check with your

state agency for regulations relating to waste.

States can also use diering terminology. For example, Washington uses

the terminology of “dangerous” and “extremely hazardous,” and regulates

“persistent” and a more broadly dened “toxic” waste. In Washington, 50% of

the hazardous (dangerous) waste generated is state-only hazardous waste.

Some states may have used oil regulations stricter than federal requirements.

In California, used oil is a hazardous waste even when it is recycled. Be aware

of both your state and federal requirements and abide by the most stringent

regulations.

7.4.2 Generator Categories

Washington regulates generators of between 100 and 1,000 kg per month

as “medium” quantity generators and calls generators of less than 100 kg

per month small quantity generators. Other states, such as Kansas, Maine,

State Requirements

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-21

Maryland, Massachusetts, Minnesota, New Hampshire, Rhode Island, and

Washington, have generator classes that vary from the federal denitions of

the generator categories. California has a “silver-only generator” status for

generators of only silver who must comply with the VSQG regulations. Kansas

requires VSQGs to use state-certied laboratories. Also, some states (such as

Kansas and West Virginia) require VSQGs to get state ID numbers.

There are no VSQG exemptions in some states, such as New York, Nevada,

Missouri, Montana, Maine, and Connecticut.

7.4.3 Recordkeeping and Reporting

Refer to

Appendix 7-4

for a summary of state-specic hazardous waste

reporting frequencies.

Some states require that the Form 8700−12, RCRA Subtitle C Identication

Form, be updated annually and submitted with the biennial or annual

hazardous waste report or on a regular schedule. In addition, some states

(such as Alabama, New Jersey, and Iowa) charge a fee to process Form

8700−12.

Some states, such as California, Maine, Maryland, Rhode Island, South

Carolina, Utah, Vermont, and Washington, have additional requirements

regarding the use of the manifest, such as state-specic waste codes and

requirements that stipulate copies must be submitted to the state agency.

Note that some states require hazardous waste records to be kept for longer

than 3 years. For instance, Washington requires generators to keep manifest

records for 5 years.

California, New York, Kansas, New Jersey, Washington, and other states

require payment of annual hazardous waste generator management fees.

7.4.4 Waste Accumulation

Some states, such as Alabama, have detailed generator storage area closure

requirements in their regulations.

Alabama’s satellite accumulation regulations have a safety exemption for the

“located near the point of generation” requirements if storage of a waste at or

near the point of generation is unsafe. This means the waste can be placed in

a location that might not be visible but is quickly and easily accessible to the

operator generating the waste.

Some states, such as California, Florida, Minnesota, and Texas, do not allow oil

lters to be placed in landlls.

7.4.5 Recycled Hazardous Waste

Note that some states have additional wastes that they regulate as universal

waste, such as aerosol cans (California and Colorado), antifreeze (Louisiana

and New Hampshire), CRTs (Maine, New Hampshire, and Rhode Island),

electronics (Arkansas, Louisiana, Connecticut, Michigan, and Nebraska), or

paint waste (Texas). In addition, Montana has additional requirements for the

treatment of electronic lamps. Contact your state agency to determine what

is regulated in your state.

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-22

In California, non-functioning CRTs are hazardous waste and cannot be

disposed of in municipal landlls. California does not exempt CRTs from

VSQGs. CRTs in California that are donated for continued use as monitors or

televisions are not identied as hazardous waste.

The state of Washington requires separate P2 plans for LQGs, excluding

commercial TSDRFs (remember that hazardous waste is called dangerous

waste in Washington).

Alaska, Iowa, Idaho, Illinois, New Jersey, Pennsylvania, U.S. territories, and

tribal lands have adopted the hazardous secondary materials exemption.

7.5 For More Information

For Information On… See…

Waste-Related Agencies

EPA Oce of Solid Waste

www.epa.gov/epawaste/index.htm

EPA Hazardous Waste Home Page

www.epa.gov/wastes/hazard/index.htm

Sector-specic Compliance

Assistance Centers (that address

real-world issues in under-

standable language for you to

understand federal environmental

requirements and how

to save

money through pollution preven-

tion techniques)

https://www.epa.gov/compliance/compliance-

assistance-centers

EPA Used Oil Management Program

https://www.epa.gov/hw/managing-used-oil-

answers-frequent-questions-businesses

Universal waste

https://www.epa.gov/hw/universal-waste

Electronic waste

www.epa.gov/wastes/conserve/materials/ ecycling

Cathode ray tubes

https://www.epa.gov/hw/cathode-ray-tubes-crts-0

Documents and References

RCRA Orientation Manual, EPA

(introductory information on the

solid and hazardous waste man-

agement programs under RCRA)

https://www.epa.gov/hwgenerators/resource-

conservation-and-recovery-act-rcra-orientation-

manual

Hazardous Waste Generator

Regulations: A

User-Friendly

Reference document, Version 6 −

August 2012

https://www.epa.gov/hwgenerators/hazardous-

waste-generator-regulations-user-friendly-reference-

document

RCRA Tools and Resources

https://www.epa.gov/rcra/resource-conservation-

and-recovery-act-rcra-tools-and-resources

Hazardous waste minimization

− Guidance to Hazardous Waste

Generators on the

Elements of a

Waste Minimization Program: 58

Federal Register 31114−31120. May

28, 1993.

https://nepis.epa.gov/Exe/ZyPURL.

cgi?Dockey=10001D8P.TXT

RCRA online database (to locate

documents,

including publications

and other outreach materials that

cover a wide range of RCRA issues

and topics)

https://rcrapublic.epa.gov/rcraonline/

For More Information

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-23

7.6 Action Items

Ite

m

Date

Started

Date

Completed

N/A Comment(s)

Identify all routine and

non-routine wastes generated

at

your facility and character-

ize

them as either hazardous

or

non-hazardous through

testing or knowledge.

Calculate the amount of

hazardous waste generated

monthly and meet the

requirements for your

gener-

ator category (LQG,

SQG, or

VSQG).

Train your sta in the proper

management of hazardous

waste on an ongoing basis

and on ways they can mini-

mize pollution generation in

their daily activities.

Inspect your central accumu-

lation areas weekly to ensure

that the wastes are

fully

contained while in storage.

Properly mark, label, and iden-

tify the hazards of the waste

on the

containers and tanks

that you use for hazardous

waste

storage.

Make sure a professional

engineer evaluates any tank

systems used for hazardous

waste storage.

Use a Hazardous Waste

Manifest or e-Manifest for

all shipments of hazardous

waste from the

facility. Take

action if your disposal facility

fails to submit a copy of the

manifest to EPA that docu-

ments the

nal disposal of the

waste.

Maintain adequate

pre-

paredness and prevention

measures,

including adequate

communications capability,

re-ghting equipment, and

other emergency response

equipment. Prepare and im-

plement a Hazardous Waste

Contingency Plan if you are

an LQG.

Manage universal waste

properly (storage, labeling).

Action Items

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-24

Ite

m

Date

Started

Date

Completed

N/A Comment(s)

Mark your used oil tanks

and containers with

the words “Used Oil,”

ensure that

secondary

containment is in place,

and ensure that you are

recycling your used oil at

a facility that is permitted

to receive it.

Maintain detailed records

of your waste manage-

ment

activities, including

waste

characterizations,

manifest

activities,

training records,

and

self-inspections.

Evaluate all materials that

move through your site

on a life cycle basis. Ensure

that

only those materials

that will minimize pollu-

tion are

brought on-site

(for example,

selecting

non-lead paint

coatings to

prevent future

generation

of hazardous waste).

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-25

Appendix 7−1 Hazardous Waste Determination Overview

Appendix 7−2 Hazardous Waste Toxicity Characteristic

Regulatory Limits

Appendix 7−3 Hazardous Waste Generator Requirements

Appendix 7−4 State and U.S. Territory Hazardous Waste

Reporting Frequency

CHAPTER 7

Appendices

THIS PAGE LEFT

INTENTIONALLY BLANK

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-27

Appendix 7-1: Hazardous Waste Determination Overview

Solid waste may include solid, semi-solid, liquid, or contained gas.

Answer this question by evaluating the following questions:

Mixtures containing listed wastes and residues from treating, storing, or disposing liquid wastes may

also be hazardous.

The material is not

subject to some

of all of the RCRA

hazardous waste

requirements

Regardless of whether the answer to Question 3 is “yes” or “no,” you must proceed to Question 4.

Mixtures containing characteristic wastes and residues from treating, storing, or disposing characteristic

wastes are hazardous if they exhibit a characteristic.

If the waste meets the denitionof hazardous waste, classif it using all applicable listed and

characteristic waste codes and manage it according to applicable regulations.

There are over 60 exemptions and exclusions in RCRA. however,

some states may not have adopted all of them.

Answer this question by evaluating the lists of hazardous waste in 40 CFR 261.31-33.

Answer this question by evaluating the four hazardous waste characteristics in 40 CFR 261.21-24.

F-list: F001-F039

Ignitability: D001 Corrosivity: D002 Reactivity: D003 Toxicity: D004-D043

K-list: K001-K178 P-list: P001-P205 U-list: P001-U411 Any state-listed wastes?

Is the material aban-

doned by being:

Thrown away;

Burned or incinerated; or

Accumulated, stored, or

treated before, or in lieu

of, being thrown away,

burned, or incinerated?

Is the material in-

herently waste-like

because it is:

A dioxin waste being

recycled, or

A secondary material

fed into a halogen-

acid furnace?

Is the material a spent material, sludge, by-product, or scrap

metal as dened in §261.1(c) or a commercial chemical prod-

uct dened in §261.33, and is it being recycled by being:

Used in a manner constituting disposal;

Burned for energy recovery used to produce a fuel;

Reclaimed, or

Speculatively accumulated?

The material may be a solid waste based on evaluation of

Table 1 in §261.2(c).

If the material is not a solid waste, is cannot be a hazardous waste and

is not subject to any RCRA hazardous waste requirements. You can stop.

If the material is a solid waste, proceed to Question 2.

1. Is it a solid waste?

2. Is it exempt?

3. Is it listed?

4. Is it characteristic?

yes

no

CFR = Code of Federal Regulations

RCRA = Resource Conservation and Recovery Act

Source: 40 CFR 261

THIS PAGE LEFT

INTENTIONALLY BLANK

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-29

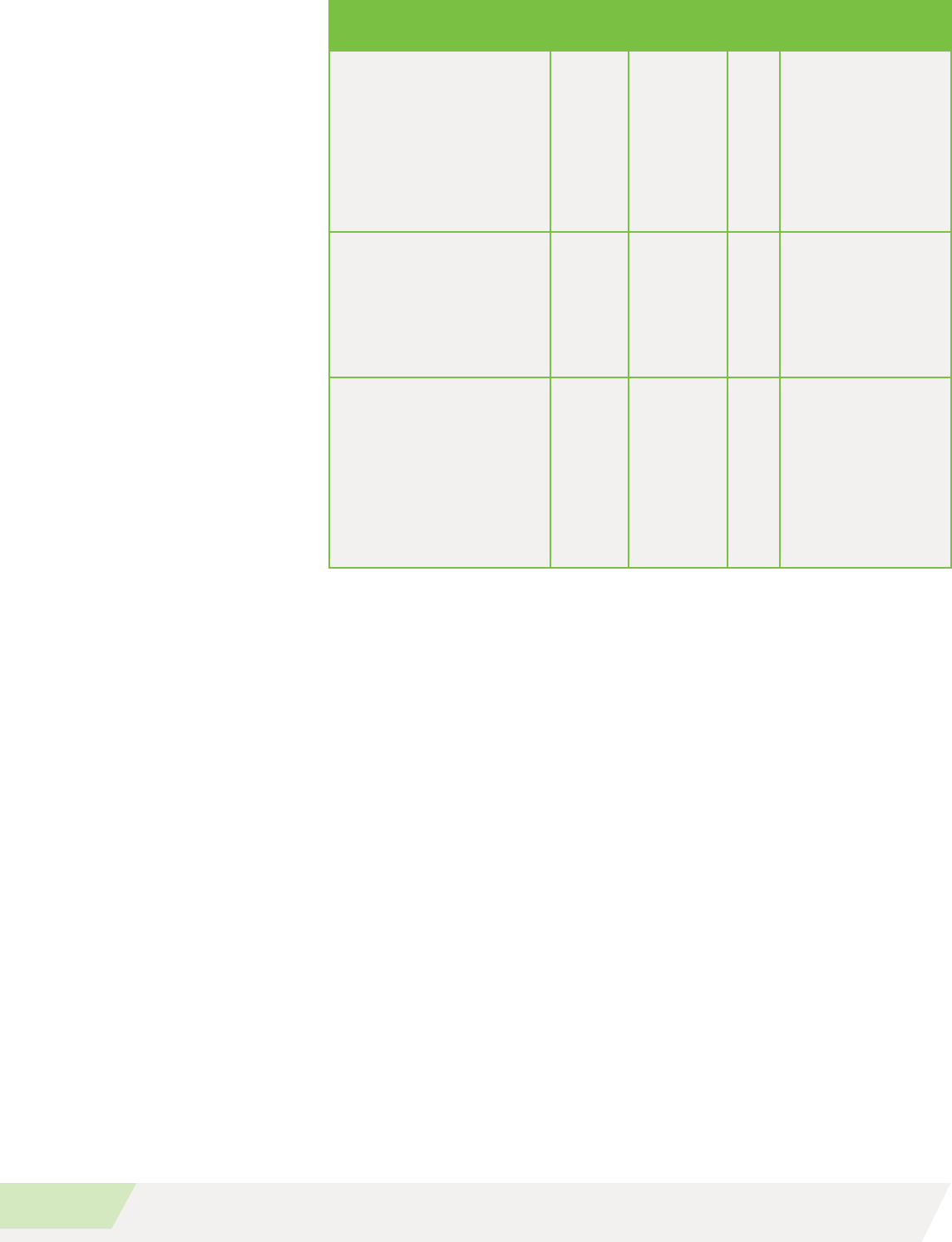

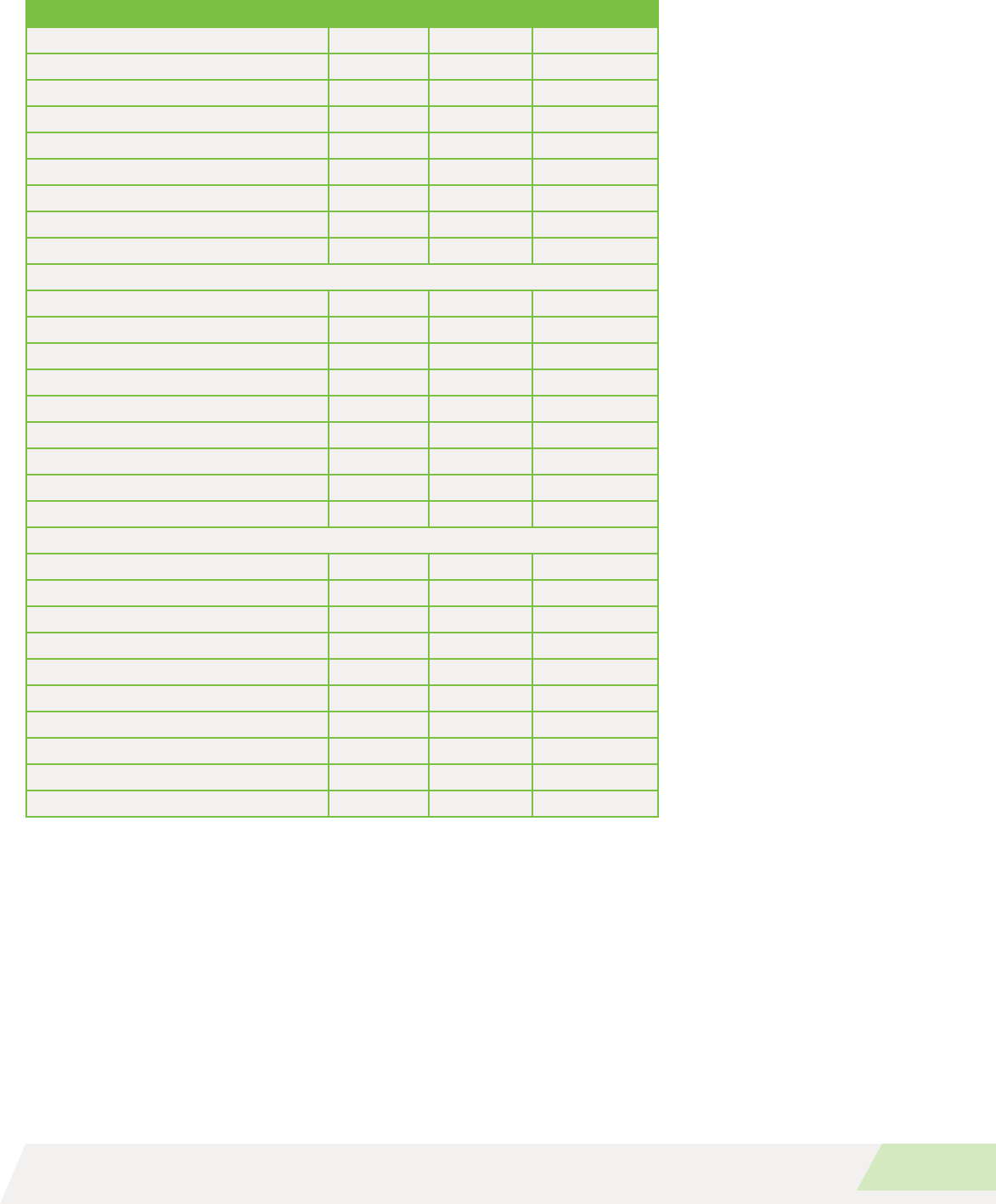

Appendix 7-2: Hazardous Waste Toxicity Characteristic

Regulatory Limits

TCLP Regulatory Limit

Metals mg/L µg/L EPA HW #

Arsenic 5.0

5,000

D004

Barium 100.0

100,000

D005

Cadmium 1.0

1,000

D006

Chromium 5.0

5,000

D007

Lead 5.0

5,000

D008

Mercury 0.2 200 D009

Selenium 1.0

1,000

D010

Silver 5.0

5,000

D011

Pesticides

Chlordane 0.03 30 D020

Endrin 0.02 20 D012

Heptachlor (and its epoxide) 0.008

8

D031

Lindane 0.4 400 D013

Methoxychlor 10.0

10,000

D014

Toxaphene 0.5 500 D015

Herbicides

2,4−D 10.0

10,000

D016

2,4,5−TP (Silvex)

1.0

1,000

D017

VOCS

Benzene 0.5 500 D018

Carbon tetrachloride 0.5 500 D019

Chlorobenzene 100.0

100,000

D021

Chloroform 6.0

6,000

D022

1,2−Dichloroethane 0.5 500 D028

1,1−Dichloroethylene 0.7 700 D029

Methyl ethyl ketone (2−Butanone) 200.0

200,000

D035

Tetrachloroethylene 0.7 700 D039

Trichloroethylene 0.5 500 D040

Vinyl chloride 0.2 200 D043

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-30

TCLP Regulatory Limit

SVOCs mg/L µg/L EPA HW #

o−Cresol (2−Methylphenol)

200.0

200,000

D023

m−Cresol (3−Methylphenol)

200.0

200,000

D024

p−Cresol (4−Methylphenol)

200.0

200,000

D025

Total cresols 200.0

200,000

D026

1,4−Dichlorobenzene 7.5

7,500

D027

2,4−Dinitrotoluene 0.13 130 D030

Hexachlorobenzene 0.13 130 D032

Hexachloro−1,3−butadiene 0.5 500 D033

Hexachloroethane 3.0

3,000

D034

Nitrobenzene 2.0

2,000

D036

Pentachlorophenol 100.0

100,000

D037

Pyridine 5.0

5,000

D038

2,4,5−Trichlorophenol 400.0

400,000

D041

2,4,6−Trichlorophenol 2.0

2,000

D042

Source: 40 CFR 261.24, Table 1

EPA HW# = The Hazardous Waste Number or code assigned by EPA to wastes with chemical concen-

trations above the specied limit.

µg/L = microgram per liter

mg/L = milligram per liter

SVOC = Semivolatile Organic Chemical

TCLP = Toxicity Characteristic Leaching Procedure

VOC = Volatile Organic Chemical

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-31

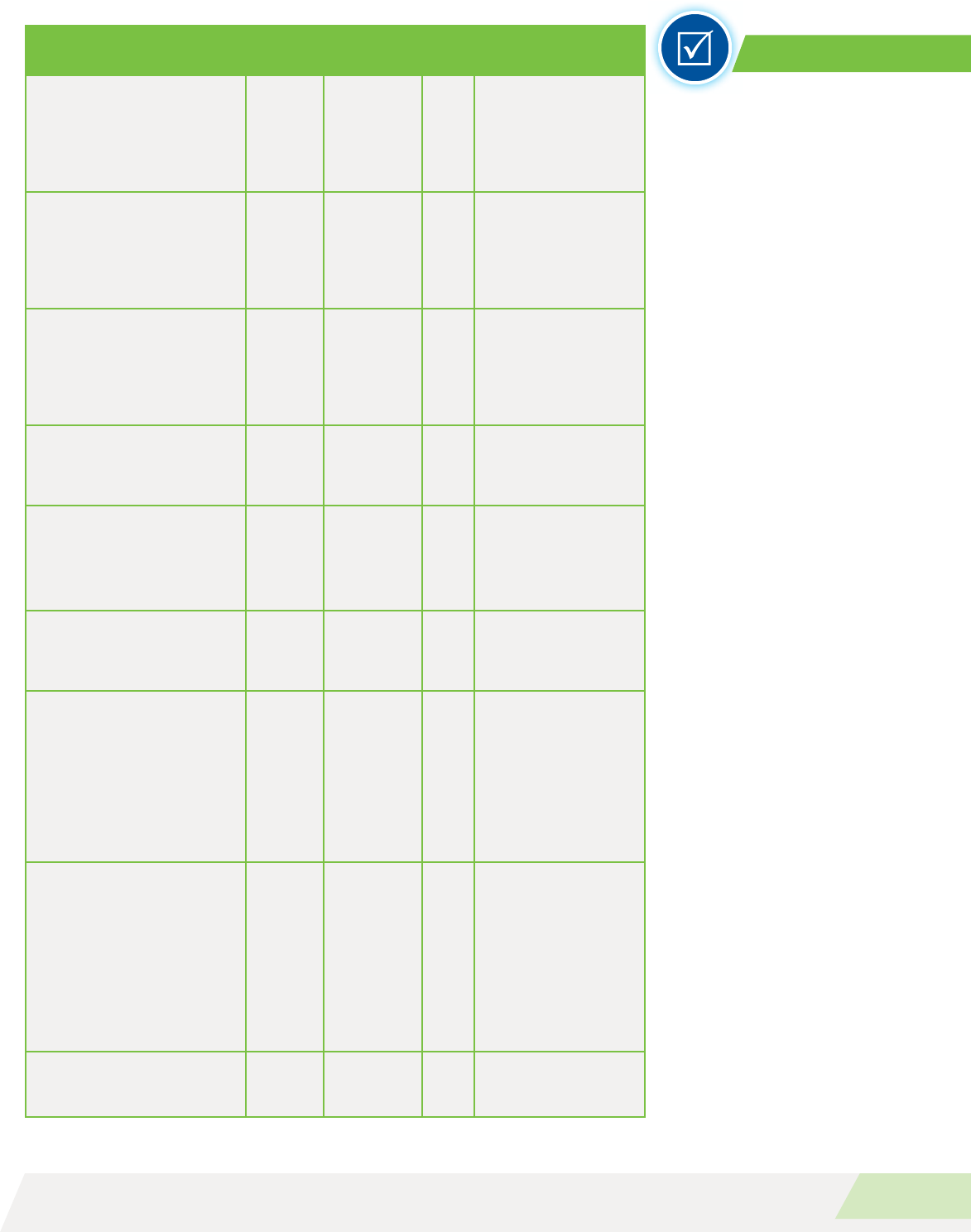

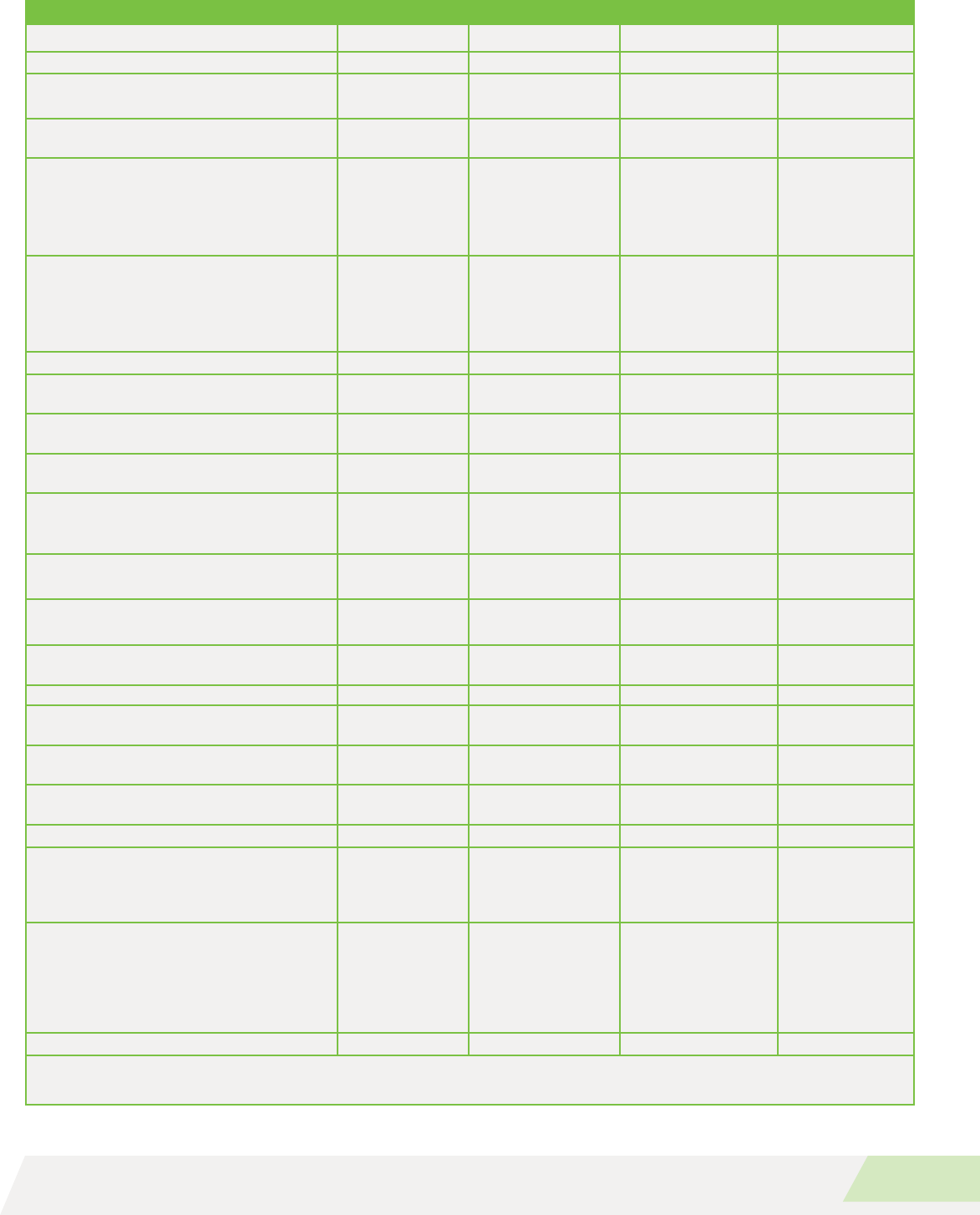

Appendix 7-3: Hazardous Waste Generator Requirements

Requirement

1

Citation in 40 CFR VSQG SQG LQG

Determination of whether waste is hazardous

261 Subpart B Required Required Required

Delivery of waste to permitted TSDRF

262.20 Required Required Required

Quantity limit generated per month:

Hazardous waste

262.13 100 kg or less 100 kg − 1,000 kg 1,000 kg or more

Acute hazardous waste

AHW-contaminated debris

262.13

1 kg or less

100 kg

1 kg or less

100 kg

Over 1 kg

Unlimited

On-site accumulation limit:

Hazardous waste

Acute hazardous waste

AHW-contaminated debris

262.13

262.14

262.16

1,000 kg

1 kg

100 kg

6,000 kg

1 kg

100 kg

Unlimited

Unlimited

Unlimited

Storage time without a permit

262.13

262.14

262.16

262.17

90 days acute waste

180 days or less (270

days or less for 200

miles or more)

180 days or less (270

days or less for 200

miles or more)

90 days or less

EPA ID number

262.18 Not required Required Required

Manifest

262 Subpart B

(262.20−27)

Not required Required Required

Container management

262.16 Not required Required Required

Tank systems

262.16

261.17

Not required Required Required

Air emission standards for tanks and

containers

265 Subpart CC

(265.1080−.1091)

Not required Not required Required

Hazardous waste label and identify the

hazards of the waste

262.16

262.17

Recommended Required Required

Accumulation date label

262.16

261.17

Recommended Required Required

Packaging, labeling, marking, and placarding

requirements

262 Subpart C

(262.30−.35)

Not required Required Required

Preparedness and prevention

262 Subpart M Not required Required Required

Contingency plan

262.17 Not required Not required Required

Emergency procedures

262.16

262.17

Not required Required Required

Personnel training

262.16

262.17

Not required Required Required

Closure

262.17 Not required Not required Required

Reporting requirements:

Biennial report

Exception report

262.41

262.42

Not required

Not required

Not required Required

> 60 days

Required

Required > 45 days

Recordkeeping requirements: Manifests and

LDR notice

Biennial report (or annual or quarterly)

Exception report

Waste analysis

262 Subpart D

Not required

Not required

Not required

Not required

3 years

Not required

Not required

3 years

3 years

3 years

3 years

3 years

Land disposal restriction notice 268.7(a) Not required Required Required

VSQG=Very Small Quantity Generator, CFR=Code of Federal Regulations, LQG=Large Quantity Generator, SQG=Small Quantity Generator,

TSDRF=Treatment, Storage, and Disposal Facility, AHW = Acute Hazardous Waste, LDR = Land Disposal Restriction

1

Check with your state agency to determine if their requirements are more stringent than federal regulations.

THIS PAGE LEFT

INTENTIONALLY BLANK

CHAPTER 7 HAZARDOUS AND RECYCLED WASTE

7-33

Appendix 7-4: State and U.S. Territory Hazardous Waste Reporting